Product Name:

Plough Paddle Dryer

Product Category:

Keyword:

Product Description

Drying process is essential in processing high Nickel product. S&L Group has developed the latest plough paddle dryer in close cooperation with leaders in Lithium battery industry.

This equipment consists of a horizontal shaft and agitator with reasonable distributed mixing paddle after static balance process. Heating jacketed cylindrical vessel body has multiple feeding ports, vent port, thermometer, pressure gauge, sample device and central discharge valve at the bottom.

The two end plates provide support for mixer body. Choppers can be added into mixing considering if the material is single crystal or polycrystalline materials. Driving system is independent from vessel body.

With the paddles made of special material, the wet mixture convectively moves along the cylinder and gets heating fully in a certain time and get uniform drying. It is widely used in high nickel lithium industry.

Advantages

♦ Wear resisting ceramic paddles

♦ Short drying time and high efficiency

♦ No metal pollution to product

♦ High grade Titanium plates for vessel working for better wear-resistant and anti-corrosion

♦ Discharge valve with air flushing to make sure no dead area, especially for high temperature

application

♦ Using special heat-resistant main shaft seal promising no leaking

♦ Anti-high temperature chopper design and seal (Optional)

♦ Mature experience for air flushing filter system

- Specifications

|

Model |

Powder (kW) |

Chopper Quantity |

Working Volume (dm³) |

Empty Weight (kg) |

|

18.5 |

2 |

0.6 |

2350 |

|

|

30 |

3 |

1.2 |

3550 |

|

|

37 |

3 |

1.8 |

4500 |

|

|

45 |

4 |

2.4 |

5600 |

|

|

55 |

4 |

3.0 |

6900 |

|

|

55 |

4 |

3.6 |

7550 |

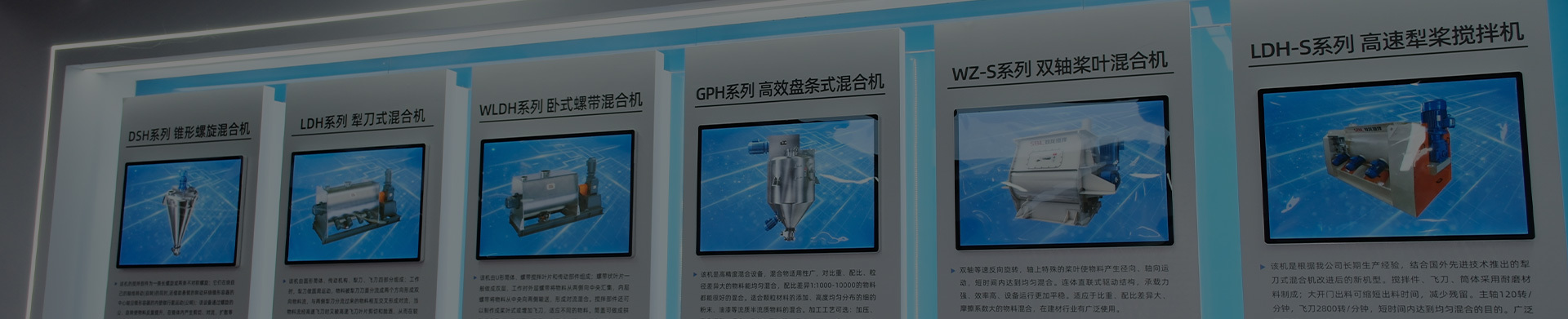

Related Products

Plough Mixer consists of horizontal & cylindrical drum vessel, plough shaped shovel agitator, drive unit and chopper. The mixing elements create a mechanical fluidized bed mixing actions to hurl materials away from the wall of vessel into free space in crisscross direction and inversely back again.

For a kind horizontal mixer, we can apply CIP to have perfect performance for hygienic production. Clean-in-Place-CIP system can be added for all our horizontal mixers.

Ploughshare Mixer With Heating/Cooling Jacket

A jacketed mixing tank is a type of container used to circulate cooling or heating fluid around the outside of the tank in order to regulate the temperature within.

Contact Us

We will contact you within one working day. Please pay attention to your email.

Industries