Product Name:

Ploughshare Mixer

Product Category:

Keyword:

Product Description

Plough Mixer consists of horizontal & cylindrical drum vessel, plough shaped shovel agitator, drive unit and chopper. The mixing elements create a mechanical fluidized bed mixing actions to hurl materials away from the wall of vessel into free space in crisscross direction and inversely back again. A fluid bed generated mechanically in this way, whereby the raw material is constantly involved in the mixing process, ensures maximum mixing intensity at even the highest feed rates and shortest residence times and allows addition of liquids. The Ploughshare Mixer guarantees extremely high performance and fully optimized processes to adapt specific mix. Plow Mixer has very fast mixing speed to get ideal mixing homogeneity in very short time and can also be used to solve multiple applications including mixing, drying, coating, reacting in one single machine. In order to meet big capacity requirement, we can also design batch and continuous mixing process for client.

Features:

● Perfect mixing result within short mixing time

● High speed chopper for de-agglomeration

● Multiple mixing elements design

● High Shearing Mixing in Movement Zone

● Heating/cooling jacket and vacuum design is optional

● Heavy duty work for complex materials

● Flexible Design for different applications and industries

● Batch or continuous process

● Center or Big bomb-bay discharge valve is optional

Applications:

● Dry Powder

● Dry Powder with liquid additives

● Slurry

● Paste and Wet

Specifications

| Gross Volume (L) | Effective Volume(L) | Overall Dimensions (mm) | Shaft Speed (rpm) | Approx. Weight (kg) | ||

| A (length) | B (width) | C (height) | ||||

| 100 | 40-60 | 1400 | 950 | 1100 | 200 | 400 |

| 300 | 120-180 | 1900 | 1100 | 1300 | 162 | 700 |

| 500 | 200-300 | 2000 | 1250 | 1500 | 145 | 865 |

| 1000 | 400-600 | 3200 | 1500 | 1900 | 134 | 2000 |

| 1500 | 600-900 | 3600 | 1600 | 1950 | 126 | 2300 |

| 2000 | 800-1200 | 3800 | 1700 | 2050 | 121 | 3100 |

| 3000 | 1200-1800 | 4200 | 1900 | 2300 | 106 | 3800 |

| 4000 | 1600-2400 | 4500 | 2100 | 2400 | 94 | 4800 |

| 5000 | 2000-3000 | 4800 | 2150 | 2600 | 85 | 5900 |

| 6000 | 2400-3600 | 5000 | 2250 | 2650 | 78 | 6400 |

| 8000 | 3200-4800 | 5600 | 2350 | 2650 | 67 | 7900 |

| 10000 | 4000-6000 | 6100 | 2550 | 2900 | 60 | 10500 |

| 12000 | 4800-7200 | 6700 | 2650 | 2820 | 54 | 13300 |

| 15000 | 6000-9000 | 7300 | 2750 | 2970 | 48 | 14600 |

| 20000 | 8000-12000 | 8100 | 2900 | 3162 | 38 | 18900 |

| 25000 | 10000-15000 | 8500 | 3100 | 3250 | 30 | 20000 |

| 30000 | 12000-18000 | 9000 | 3300 | 3300 | 25 | 23000 |

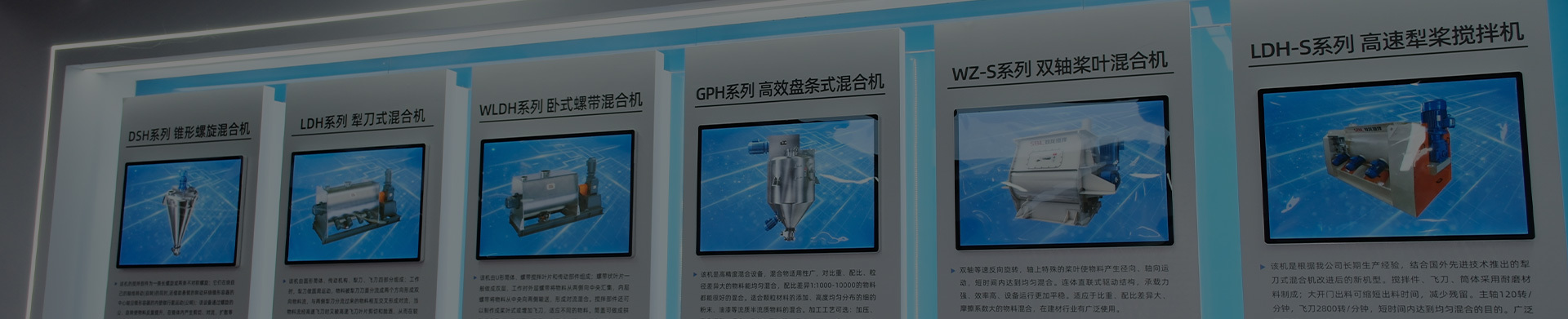

Related Products

For a kind horizontal mixer, we can apply CIP to have perfect performance for hygienic production. Clean-in-Place-CIP system can be added for all our horizontal mixers.

Ploughshare Mixer With Heating/Cooling Jacket

A jacketed mixing tank is a type of container used to circulate cooling or heating fluid around the outside of the tank in order to regulate the temperature within.

Ploughshare Mixer With Retractable Shaft

For some special applications and industries, retractable rotor plough share mixer is necessary because if manual cleaning and CIP cleaning cannot meet customer’s requirement, the shaft need to be pull open to clean manually, especially some materials stick on mixing elements.

Contact Us

We will contact you within one working day. Please pay attention to your email.

Industries