Product Name:

Continuous Mixer

Product Category:

Keyword:

Product Description

Different from traditional batch type mixer, continuous mixer provide a more economical alternation for big capacity to meet process requirement. The weighing, loading, mixing and discharge steps finish simultaneously and continuously in a continuous mixing process. For many applications, continuous mixing offers a cost effective alternative to traditional batch mixing with lower processing costs and fewer labor requirements. The continuous mixer can handle up to 5 different materials at one time, mixing powders with another powder, powder with a liquid or several liquids together to create a homogeneous product free of any agglomerates or lumps.

Features:

● Different types of mixing elements can be designed such as paddle, plough shovel and ribbon etc.

● Adjustable mixing elements and shaft speed for flexibility to mix a wide variety of materials in an efficient manner.

● De-agglomerate device can be added for applications where materials need to be de-agglomerated.

● Big Capacity is available for wide range of applications and industries.

Applications:

- Mining enterprise, municipal department, metal processing industry: blending mineral powders, sludge mixture, etc.

- Applicable Materials

- S&L horizontal ribbon mixer is suitable for mixing and blending powders and powders, particles and powders, as well as powders and small amounts of liquid additives.

- Additional Functions

- Pressure/vacuum inside mixer, Jacket for cooling or heating

Detailed Description:

A. High speed

Continuous mixers are generally driven by gear reducers, and the motor uses a variable frequency motor to adjust the speed. The spindle speed is several times higher than that of intermittent mixers to ensure the mixing effect.

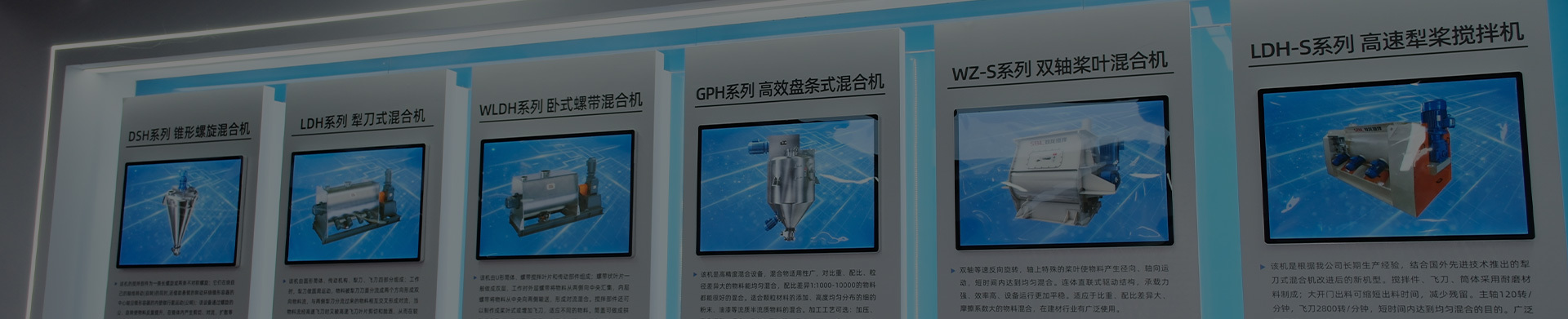

B. Mixer form one

Because of the different characteristics of the materials, different agitator types are used, such as paddle type and ribbon type as shown in the picture.

C. Mixer form two

Because of the different characteristics of the materials, different agitator types are used, such as the plow type and the double-shaft paddle type as shown in the picture.

D. Atomizing nozzle

An atomizing nozzle can be added above the flying knife to achieve liquid addition and mixing. Since the material at this position has a smaller density under shearing by the flying knife, the atomized liquid material is more likely to enter and mix with the powder.

E. Optional flying knife

For some special materials, a flying knife can be optionally used to deaggregate and break up the materials.

F. Feeding method

The feed generally uses a screw conveyor or a belt conveyor, and a frequency converter is used to adjust the feed speed to match the discharge speed of the mixer.

Mixer with Retractable Rotor

The retractable rotor mixer has been developed to meet the needs of specific applications and industries. In cases where manual or CIP cleaning cannot thoroughly remove any materials that may have become stuck to mixing elements or in hard-to-reach areas, the shaft can be completely retracted for further cleaning. This design enables customers to entirely solve the problem of cleaning viscous materials and performing maintenance tasks in the future. The unique design reduces downtime for cleaning and minimizes the potential for cross contamination. An easy to access mixing chamber ensures a hygienic mixing environment.

Working Principle

The retractable rotor mixer is equipped with a quick clamp structure between the end plate and end flange of the vessel body. The shaft can be conveniently and quickly opened away from the vessel. The input shaft connects to the reducer and is held in place by the reducer bearing, while the other side of the shaft is positioned by two bearings. The rail guide ensures that the shaft can be fully opened and driven by a motor or manually operated. However, a PLC control system is required to operate the machine, and a position sensor is needed to ensure that the shaft stops at the same position if it needs to be pulled open.

Related Products

Conventional Jacket Mixer with ASME

A jacketed mixing tank is a type of container used to circulate cooling or heating fluid around the outside of the tank in order to regulate the temperature within.

Continuous Mixer With Heating/Cooling Jacket

For a kind horizontal mixer, we can apply CIP to have perfect performance for hygienic production. Clean-in-Place-CIP system can be added for all our horizontal mixers.

Contact Us

We will contact you within one working day. Please pay attention to your email.

Industries