Product Name:

Double Paddle Mixer

Product Category:

Keyword:

Product Description

Twin Shafts Paddle Mixer consists of W shape vessel, drive unit and double paddle shafts. The double shafts run in counter-rotation to make paddles turn over the materials in axial and radial direction of mixing action in fluidized zone. All the materials will be lifted in non-gravity status and also fall down to form a cross mixing. We can get perfect homogeneous mixing in very short time and almost all the materials can be emptied through full bottom discharge valve. Liquid Additions can also be sprayed at top of cover and mix with powder in short time. For some heat sensitive and fragile material, twin shafts paddle mixer can fulfill perfect mixing result.

Features

● Excellent mixing homogeneity in rapid time

● Abrasion resistant and heavy duty design for some abrasive material

● Big size discharge valve to minimize residues

● Top high speed lump breaker device for de-agglomeration requirement

● Batch or Continuous type is available

Applications

● Dry Powder

● Dry Powder with liquid additives

Detailed Description:

A. Mixed effects

This machine is a high-precision mixer. Even if the materials have huge differences in specific gravity, particle size, and proportion, it can achieve good mixing effects under the rapid and violent tumbling and throwing of the staggered mixing blades. After actual measurement, the highest mixer uniformity coefficient of variation CV value of this machine can reach ≤3%.

B. Crushing device

When the material has aggregation and agglomeration, a crushing device needs to be added. The "crushing rod" with a triangular gear cover maintains a high speed of more than 1000 rpm to crush and deagglomerate the agglomerated material in the weight loss area of the material.

C. Discharging form

The discharge form is generally a pneumatic flap valve. The arc valve is tightly embedded in the cylinder and is flush with the inner wall of the cylinder. There is no material accumulation or mixing dead angle. The standard type has a large door and a small door. The large door opens to the edge of the cylinder and is placed The material is clean and fast, with little residue.

D. Two-piece blade

In order to reduce the cost of replacing wearing parts of the equipment, the propeller blades can be made into two pieces. A small movable blade is placed on the blade base, and the worn small blades can be directly replaced, which is economical and fast.

E. Direct-coupled reducer

For large mixers with more than 6 cubic meters, in order to increase the torque and reduce the maintenance rate, a direct-coupled gear reducer is used, which effectively solves some previous defects.

F. 20 cubic meters full volume

This series of mixers can have a maximum full volume of 20 cubic meters. The transmission form and mixer base of large-sized equipment are very different from ordinary specifications.

Specifications

| Gross Volume (L) | Effective Volume (L) | Overall Dimensions (mm) | Shaft Speed (rpm) | Approx. Weight (kg) | ||

| A (length) | B (width) | C (height) | ||||

| 200 | 80-120 | 1200 | 1200 | 750 | 43 | 270 |

| 300 | 120-180 | 1300 | 1400 | 930 | 43 | 450 |

| 500 | 200-300 | 1500 | 1600 | 1050 | 43 | 900 |

| 1000 | 400-600 | 1900 | 1600 | 1200 | 43 | 1190 |

| 1500 | 600-900 | 2200 | 1700 | 1325 | 43 | 1600 |

| 2000 | 800-1200 | 2400 | 1700 | 1600 | 43 | 2700 |

| 3000 | 1200-1800 | 2500 | 1850 | 1760 | 43 | 3200 |

| 4000 | 1600-2400 | 2900 | 2200 | 1850 | 29 | 4500 |

| 5000 | 2000-3000 | 3100 | 2300 | 2040 | 29 | 6000 |

| 6000 | 2400-3600 | 3300 | 2500 | 2100 | 29 | 7000 |

| 10000 | 4000-6000 | 3800 | 2900 | 2500 | 29 | 9000 |

| 13000 | 5200-7800 | 4200 | 3200 | 2500 | 25 | 9700 |

| 15000 | 6000-9000 | 4400 | 3400 | 2600 | 25 | 11000 |

| 18000 | 7200-10800 | 4700 | 3700 | 2500 | 25 | 12500 |

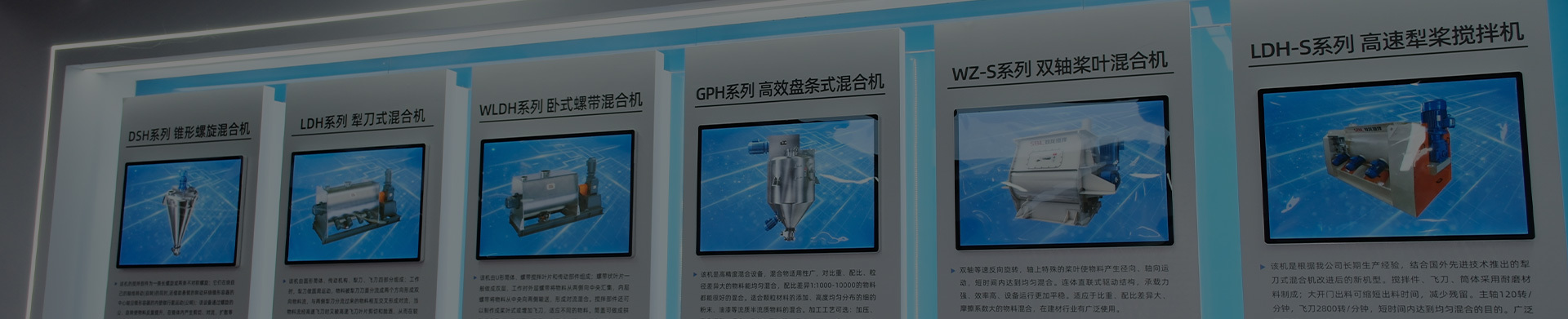

Related Products

For a kind horizontal mixer, we can apply CIP to have perfect performance for hygienic production. Clean-in-Place-CIP system can be added for all our horizontal mixers.

Double Paddle Mixer With Heating/Cooling Jacket

A jacketed mixing tank is a type of container used to circulate cooling or heating fluid around the outside of the tank in order to regulate the temperature within.

Double Paddle Mixer With Retractable Shaft

Retractable rotor mixer is developed to meet with some special applications and industries. Sometimes the manual cleaning and CIP cleaning cannot work perfectly for thoroughly cleaning, the shaft need to be retractable completely to have further cleaning.

Contact Us

We will contact you within one working day. Please pay attention to your email.

Industries