Product Name:

High Temperature Cladding Kettle System

Product Category:

Keyword:

Product Description

Horizontal reactor is a key equipment for coating and granulation of anode lithium battery material. The whole equipment adopts horizontal structure, and the cylinder body is circular structure and welded with both ends head as one. The material is heated by thermal radiation from a external heating wire and maximum design temperature could be 650℃. The material temperature could be adjusted between 350-650℃and variable production temperature can be achieved. All this can well meet the needs of production conditions of high efficiency and variable temperature. The equipment could be stable and durable working in high temperature working condition.

Advantages:

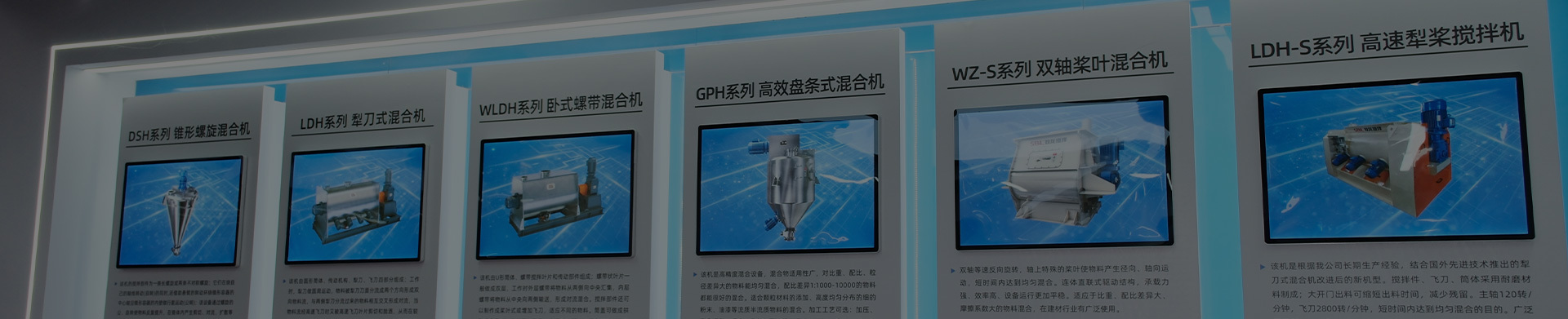

With development of new energy vehicles, the demand of Lithium battery raw material is increasing heavily. Mixing is certainly an essential process during production. There used to be some problems such as small contact area with materials, low mixing uniformity, long mixing time, and equipment height restrictions. In order to reach the market needs, S&L Group developed this equipment, with the advantages of high mixing uniformity, short mixing time, and better plant size adaptability. It now proves to be widely used in lithium battery industry.

♦High Efficiency

Wider inner and outer ribbon elements to have stronger mixing, shorter mixing time and good mixing homogeneity.

♦ Stable Working

Coupling between main shaft and driving system does good to avoid vibration under high temperature. It can protect the driving system from overloading as well.

♦Min. Residues

Adjustable scrappers on main shaft can minimize the gaps between scrapper and two ends plates, and as well as for gaps between scrapper and vessel bottom to have min. residues.

Related Products

Contact Us

Industries